|

Search | FAQ | US Titles | UK Titles | Memories | VaporWare | Digest | |||||||

| GuestBook | Classified | Chat | Products | Featured | Technical | Museum | ||||||||

| Downloads | Production | Fanfares | Music | Misc | Related | Contact | ||||||||

| Featured CED Patent No. 4,145,718 | ||||||||||||||

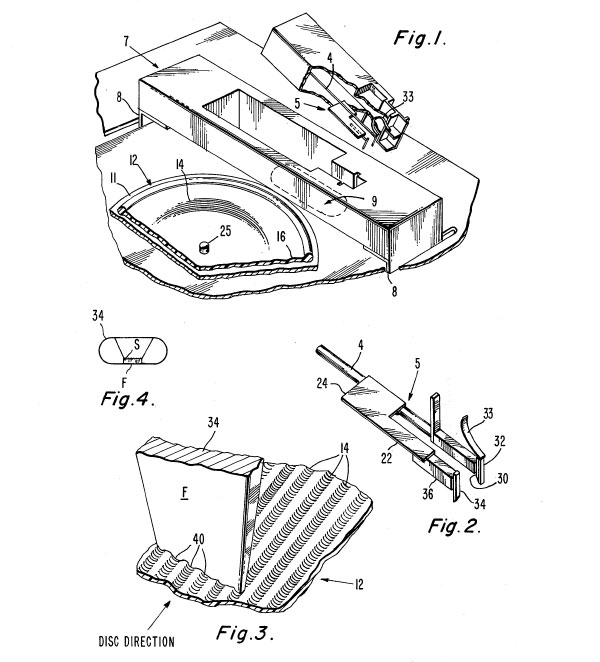

"One problem associated with the operation of an information recording and playback system of the above-described type to recover the recorded information is the presence of dust and debris particles in various regions of the disc groove. Playback stylus encounters with such dust and debris particles often result in the deflection of the playback stylus out of engagement with the bottom of the groove leading to momentary distress or loss of information signals. More severe encounters may result in the playback stylus skipping several groove convolutions at a time leading to the loss of plurality of frames of video information. Dust and debris particles in groove regions may also be responsible for locked groove incidents resulting in the playback stylus retracting the same path. Moreover, these encounters may result in the rapid wear of the disc and the signal pickup electrode (e.g., as the playback stylus lands on the rapidly rotating disc surface after being deflected)."This patent addresses the skipping issue by suggesting the use of a preplay or scraper stylus to clean several grooves at a time prior to being reached by the actual playback stylus. Fig. 1 above shows how the stylus cartridge fits into the player mechanism, while Figs. 2, 3, & 4 show moderate and extreme enlargements of the stylus mechanism. Referring to Fig. 2, the stylus pickup (5) is forked with the playback stylus (30) being one tip, and the preplay stylus (34) being the other tip. A single flylead (33) supports both tips and provides the necessary pressure for groove tracking. RCA estimated tracking pressure to be 90 milligrams for the playback stylus and 40 milligrams for the preplay stylus (this compares to 65 milligrams for the production system in 1981).

Fig. 3 shows an enlargement of the preplay stylus (34) and eight grooves (14) on the surface of the VideoDisc (12). The tip of the preplay stylus has six projecting areas (40) shaped to conform to the grooves and gives the preplay stylus the ability to clean six grooves simultaneously. The advantages of this construction was that it tended to keep the preplay stylus on track, and the preplay stylus had a lot of inertia. One issue that comes up with the system RCA actually marketed is that stylus will simply bounce off particularly obstinate pieces of dust seemingly glued to the surface of the disc and many repeated plays of the same groove may be necessary to break the contaminant loose. With this preplay stylus the mere mass of the tip might break such a dust particle loose on the first pass, and the tip still had five more revolutions to get it loose before the playback stylus got to that groove.

With these advantages in skipping reduction, why didn't RCA implement the preplay stylus in the production system? I can think of three compelling reasons. The No. 1 problem with dust contamination in 1977 was the locked groove condition where the stylus would play the same groove over and over again. RCA knew they had to find a way to minimize this problem, and the preplay stylus was one alternative. But by 1980, the still relatively new ROM-customized microprocessors had dropped substantially in cost, and RCA incorporated one into the SFT100 player to eliminate locked groove via stylus kicking; plus the microprocessor provided a number of other system control functions. The second reason was RCA's decision to house CED's in caddies, which eliminated the risk of contamination that might occur if the owner left unprotected discs lying around. The third reason for not implementing a preplay stylus was the fact that even with reduced pressure on the disc, playing a disc once with a preplay stylus mechanism was like playing it several times with just a playback stylus. Matsushita through their subsidiary JVC was at this time developing a copy-cat CED system called VHD that was grooveless when it finally hit the market. But in one of their patents, the company actually references the problems with a preplay stylus on a grooved VideoDisc:

"On the other hand, a conventional video disk, depending on the type, is provided with a thin coating layer of a lubricant on the surface thereof in order to decrease the abrasion of the playback stylus and the record disk. It was revealed in the test of applying a shaving means with teeth for such a record disk that the shaving means scrubbed the lubricating coating layer and that the playback stylus and the record disk were remarkably abraded. It is easily understood that the abrasion of the recorded signal patterns in the grooves and the scrubbing of the lubricating coating layer are accelerated when the number of the teeth at the shaving means becomes large, since the grooves are scrubbed as many times as the number of the teeth."

So with CED system as marketed by RCA, I believe we are better off not having had this preplay approach, but it does bring up the question of how to reduce skipping on CED's, which is probably one of the most frequent topics on CED Digest. After first making sure the stylus cartridge itself isn't worn out, my suggestion has been to use the repeated playback of the groove as the only guaranteed safe way to eliminate skipping. Others have suggested various means to reduce skipping by washing the disc or treating it chemically, but no one can say for certain what effect that will have on the disc 20 or 30 years in the future. If you'd like to see some of the suggestions that people have made try searching CED Digest for terms like skipping and cleaning. My recommendation is to only wash discs with water when they have been exposed to extreme contamination (like muddy water) and make the final rinse with distilled water. Keep in mind that even this simple washing will remove the silicon lubricant from the surface of the disc and reduce its lifespan, but in this case the disc would have been unplayable otherwise.

One issue with skipping concerns discs that have sat for many years without being played. This even applies to brand-new discs still in their shrinkwrap. In these instances the discs often skip frequently the first time being played, and exhibit little skipping thereafter. Discs that have never been played or maybe only played a couple of times and then put away for years will have a glassy smooth consistency to the lubricant on the disc surface that contributes to frequent skipping. By playing the disc, the stylus tip in effect cuts a "groove" in the smooth lubricant making it far less likely the skipping will occur the next time the disc is played. Whenever I load a disc that exhibits skipping of this nature, I simply play the disc all the way through with the TV turned off, and then watch it on the second play. Discs no longer in their original shrinkwrap may also have been exposed to contamination by minute dust particles that can be removed to a large extent by vacuuming the disc prior to playing it one time without watching it. There is a company called Nitty Gritty that makes an LP vacuum that can be modified for CED use, but I wouldn't recommend using their cleaning fluid in conjunction with the vacuum due to the possibility of a long-term chemical reaction with the lubricant on the CED surface. If you have an Audio LP turntable and a conventional floor vacuum, a comparable CED vacuuming system can be improvised as illustrated in the following photograph:

This is used by placing the CED to be vacuumed on the turntable with an inverted coffee mug over the center of the disc providing additional weight to hold it in place. The crevice attachment is used on the vacuum cleaner to provide the maximum amount of suction. With the turntable spinning, the crevice attachment is brought as close to the disc surface as safely possible and simply held there to vacuum the disc surface spinning underneath. it's important to use both hands and brace them firmly as shown in the photo.

One final thing to keep in mind with skipping, is that with physical damage, no treatment, chemical or otherwise, is going to repair the damage and eliminate skipping. Physical damage could be caused by discs being stored improperly in a flat stack, discs damaged by some other overlying weight either in storage or while being shipped, or discs that have simply lived their useful playback life. Rental discs and discs owned by children may have been played so many times that the groove walls have been worn down by repeated plays, repeated loading in the player, and nonchalant handling of the caddy with the disc inside. For me, skipping is a non-issue, as I've replaced most of the rental disc in my collection, and on good-condition discs that exhibit skipping from the start, the "vacuum and playback once without watching" technique almost always eliminates the skipping. I can only assume the horror stories I've heard from people who complain about every disc in their collection skipping to no avail are attributable to a worn out stylus cartridge or the entire collection being of rental origin.